Understanding the Pricing Puzzle in Plastic Molding

If you’ve ever worked with a plastic molded parts manufacturer, you know that pricing isn’t as simple as just quoting a number per piece. Behind every price tag is a detailed calculation that considers material selection, mold design, production volume, and even the complexity of the part itself. Many first-time buyers are surprised to learn how much effort goes into building an accurate price structure.

In my experience working with manufacturers and clients across different industries, the real value comes from understanding these variables. Whether you’re sourcing parts for automotive applications, consumer electronics, or medical devices, knowing how a plastic parts company sets its prices helps you budget wisely and avoid unexpected costs.

Material Choice: The Starting Point of Pricing

One of the biggest contributors to cost is the type of resin used. Commodity plastics like polypropylene (PP) or polyethylene (PE) are far more affordable than engineering plastics such as ABS, nylon, or polycarbonate. But material choice isn’t just about cost per pound—it also influences the durability, appearance, and performance of the part.

A plastic molded parts manufacturer will usually guide you through the trade-offs. For example, if you’re building a lightweight consumer product, they may suggest polypropylene because it offers a good balance of price and performance. If your project involves heat resistance or impact strength, however, you may end up paying more for an engineering-grade resin.

Resin availability also plays a role. During global shortages, prices can spike, and a plastic parts company may pass these additional expenses on to the customer. This is why some manufacturers suggest alternative resins that provide comparable performance but at a more stable cost.

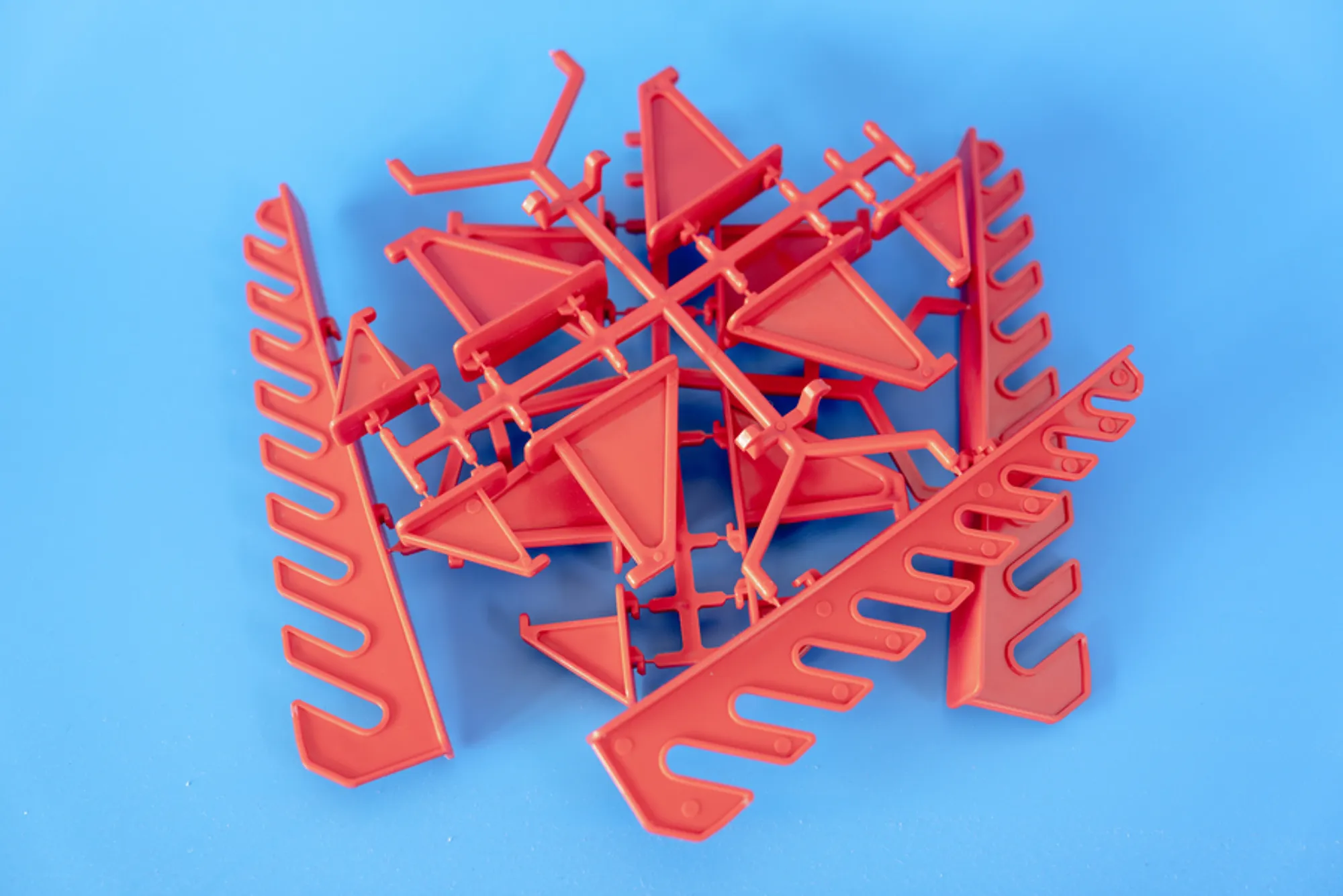

Mold Design and Tooling: The Hidden Investment

One of the least understood aspects of injection molding pricing is tooling. Before a single part is produced, a mold has to be designed and fabricated. This is often the most expensive upfront cost. Depending on the complexity, tooling can range from a few thousand dollars to hundreds of thousands.

The precision of the mold determines the final quality of the product. Multi-cavity molds (which allow multiple parts to be produced per cycle) cost more but drastically reduce per-unit costs in high-volume runs. A plastic molded parts manufacturer will evaluate your projected order size before recommending a tooling strategy. If you plan to produce millions of units, investing in a high-quality steel mold makes sense. But if your run is small, aluminum molds might be a more economical choice.

In many cases, clients underestimate tooling costs because they focus only on per-part pricing. But tooling is an investment. Over the lifetime of production, the upfront cost pays off by ensuring consistency and efficiency.

Production Volume: Why Quantity Shapes Price

Volume is perhaps the most critical factor in determining per-unit cost. Injection molding thrives on economies of scale. The more units you order, the lower the cost per piece, because the fixed expenses of setup, tooling, and labor are spread across a larger batch.

A plastic parts company often uses tiered pricing to reflect this reality. For example, 10,000 parts might cost $1.50 each, but scaling up to 100,000 units could drop the cost to $0.50 per unit. That’s why clients planning for growth often commit to higher volumes to maximize savings.

Low-volume runs, on the other hand, are less efficient. They require the same setup and tooling but don’t benefit from bulk material purchases or reduced machine downtime. This explains why short runs usually carry a premium price.

Part Complexity and Cycle Time

Not all parts are created equal. A simple flat piece takes less time to mold than a part with undercuts, intricate detailing, or multiple wall thicknesses. Every design feature influences cycle time—the length of time it takes to mold, cool, and eject a part. Longer cycles mean fewer parts per hour, which directly increases costs.

A plastic molded parts manufacturer may recommend slight design modifications to optimize cycle time. For instance, adding uniform wall thickness or minimizing sharp angles can improve cooling efficiency, reduce defects, and cut costs. Design for manufacturability (DFM) is an essential practice that helps both parties balance quality and affordability.

Secondary operations such as painting, assembly, or packaging also impact the final price. A plastic parts company that offers value-added services will factor these into the overall cost structure.

Labor and Overhead Costs

Although injection molding is highly automated, human expertise is still required. Skilled engineers design molds, set up machines, and oversee quality control. Labor costs vary depending on the region, with manufacturers in Asia often providing more competitive rates compared to those in North America or Europe.

Overhead costs such as energy, maintenance, and facility expenses are also built into the final pricing. For example, running high-tonnage presses consumes significant amounts of electricity, and those costs eventually trickle down into unit pricing.

Quality Assurance and Certification

In industries like automotive or medical devices, quality assurance is non-negotiable. Meeting ISO, FDA, or automotive-grade certifications requires extra inspections, documentation, and testing. These quality-control measures add to the overall cost but also ensure compliance and reliability.

A reputable plastic molded parts manufacturer will be transparent about these additional costs. They aren’t just charging for parts—they’re guaranteeing performance and safety.

Shipping and Logistics

Even after production, logistics can influence pricing. Shipping bulky or heavy parts across long distances adds cost. Some clients choose local suppliers to minimize freight charges, while others offset higher logistics costs with lower manufacturing rates overseas.

A plastic parts company that operates globally might even recommend splitting production between locations to optimize both costs and delivery timelines.

The Value of Transparency in Pricing

What ultimately separates a reliable partner from the rest is transparency. A professional plastic molded parts manufacturer won’t just provide a number—they’ll break down the reasoning behind it. When manufacturers explain how material, tooling, volume, and labor factor into pricing, clients gain confidence and clarity.

Likewise, a trustworthy plastic parts company will work with clients to find cost-saving opportunities without compromising quality. Whether that means suggesting an alternative resin, tweaking part design, or scaling order volumes, collaboration leads to smarter pricing strategies.

Final Thoughts: More Than Just a Price Tag

Pricing in injection molding isn’t arbitrary—it’s a careful balance of design, material, production, and quality. By understanding the factors that influence costs, businesses can make informed decisions and build stronger partnerships with their suppliers.

If you’re planning to work with a plastic molded parts manufacturer, don’t just ask for a quote. Ask for a breakdown. A clear explanation not only helps you budget accurately but also ensures your product is manufactured with the quality, efficiency, and reliability your market demands.